When navigating inclines or declines, forklift operators should continue to keep a secure distance involving their vans and go at a reasonable pace.

The cope with is often Geared up that has a horn button, enabling them to warn pedestrians together with other devices operators without the need to convert all around and press the horn within the steering wheel.

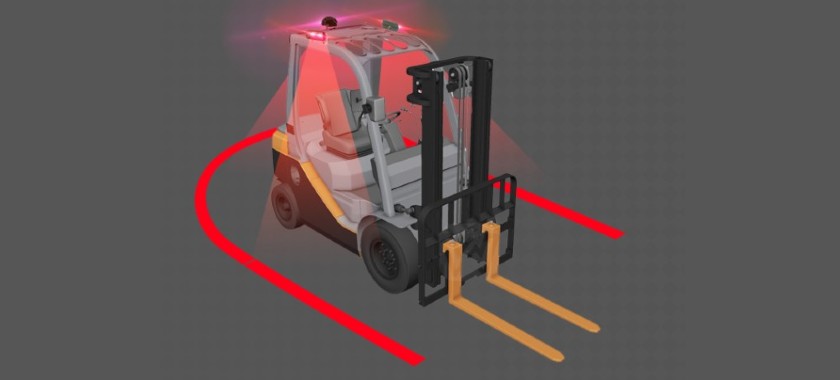

One of the variety of safety options built-in into forklifts, safety lights are especially critical. This article will delve into 7 unique kinds of forklift safety lights, elucidating their part in boosting worker safety.

Under the OSHA prerequisite, forklifts need to be Geared up with lights and horns when office disorders have to have them. This prerequisite ensures that audible and visual warnings are readily available to circumvent likely dangers and promote safety.

One more OSHA prerequisite outlined in its forklift safety rules would be the inclusion of tail/brake lights, which are usually presently developed into forklifts. These lights Enhance visibility and decrease the probability of mishaps in crowded operate environments.

When not obligatory for forklifts running in fewer congested parts, OSHA strongly suggests putting in them on forklifts that operate in high-visitors zones with numerous pedestrians.

Like blue forklift safety lights, this distance could be adjusted forklift lights safety by angling the light. To be certain safety, pedestrians along with other forklifts mustn't cross this halo line.

When safety lights are set up with a forklift, operators need to ensure the lights are Doing work properly In the beginning of every change. Don't forget to include “inspect safety lights” to your forklift pre-shift inspection checklist and coach operators how to inspect and use the lights.

Utilize a tape way to indicate the specified path for navigation all through the facility. To avoid confusion, consider blocking off regions that forklift operators should not accessibility.

LED lamps are Vitality economical, consuming significantly less ability in comparison to standard bulbs. Due to their successful energy provision, expenditures are diminished and set much less pressure on the electrical method.

Headlights illuminate function spots and support forklift operators be more effective - operators who are forklift lights safety sixty+ will need 3x as much gentle to determine the same issue as a 20-calendar year-previous

Employing a forklift forklift lights safety with lights for the specific job you happen to be executing is critical. If you alter forklifts to do a different occupation, you might have a different lights forklift lights safety set up. Always check together with your safety coordinator to ensure you have the proper lighting for the forklift lights safety job.

Secondary lights on forklifts usually implies its for that forklifts to operate as safely and easily as you can from the place of work. Secondary forklift lights consist of rotating and flashing beacons, operate lights, and projection safety lights.

Moreover, forklifts greatly enhance efficiency by relieving workforce stress, completing jobs quickly in a single sequence. Their compact design and style makes it possible for qualified manoeuvrability in confined Areas, and Irrespective of their sizing, forklifts boast extraordinary lifting capacities, making certain ideal productiveness with less methods.